Just a side note to start: This might seem obvious but…. When you make any change the dilution tank will need to be drained before you will know if you fixed the problem. Yes you will be able to see chemical being pulled into the dilution tank when you fix the problem…. So you could wait. 🙂 I was just addressing the fix will not be instant for the foam brush. The dilution tank is filled with water and needs the correct dilution of chemical for the foam brush to work correctly again..

When you are troubleshooting a foam brush problem it can be lots of problems. This time the issue was “none of the foam brushes are working”.

- So the first thing to do is verify if it is really all the bays are not working. Always verify.

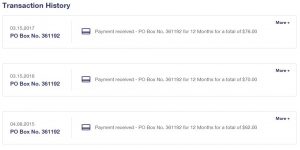

Next check your dilution tank or holding tank…. Just check your tank with your hydrominder in it. You are checking to see:

- Is your hydrominder stuck?

- Is the chemical hose connected?

If the hose and hydrominder seem to be working properly it is probably the next item.

I have had every problem ever with foot valves. Yes you need them and yes they go bad especially in harsh chemicals. (The gray foot valves are for harsher chemicals.) There is also a reason I use pvc. (Maybe 2 feet?) This makes the new hose straight and when the hose hardens over time it will be easier to pull out of the chemical drum.

-

- Check your chemical…. Do you have any? 🙂

- Check to make sure your hose and foot valves are under the chemical line. This allows the hydrominder to suck the chemical needed for the foam brush.

- You can check the foot valve…. maybe clean it? But I would replace the foot valve if that is the problem.

I am not sure…. but hydrominder troubleshooting may need its own how to? LOL 🙂 I was trying to make this simple for someone. 🙂

But hydrominders are also not complex either…. you can also just replace a lot of the parts which are sold separably.

- Check hose seal on hydrominder…. Some times the hose can get to fat or crack…. basically pull air which is bad.

- Check the hydrominder water pressure…. If the water is barely coming out you might have some sort of build up in the hydrominder.

- Check the hydrominder for cracks…. Usually you will know there is a problem like the picture above. 🙂

- Check the post alignment…. Sometimes the post (or whatever it is called) is off and causes it is randomly stick.

So my chemical drum tips:

- Never put the draw hose all the way at the bottom of the drum. If something goes wrong all your chemical could get sucked out!

- Use around 2 feet of pvc to keep the hose straight and everything cleaner…. maybe. 🙂

My hydrominder tips:

- Use stainless screws…. Are these really not included? 🙂

- Keep some parts on hand…. I had a couple full spares and way to many individual parts. If this breaks you are in trouble. 🙂